Weld Preparation

Before workpieces can be welded together, the welding edges must be prepared.

On one hand this is necessary to achieve optimum dimensional accuracy and on the other hand it is important to prevent undesirable substances from entering the weld pool, which could have a negative influence on the quality of the weld seams.

WELDING SURFACE CLEANING, BEFORE AND AFTER WELDING

Welding Seam and Seam surface cleaning is definitely one of those classic applications of industrial laser cleaning. It can be applied on steel, stainless steel and aluminium welds without damaging the substrate.

STEEL

Weld preparation and weld cleaning are vital in the steel processing industry. A laser system can effortlessly be built into an existing process or production line, speeding up the complete process. Weld preparation is a crucial step before actually placing a weld and can be done with surface cleaning. Laser cleaning on mild steel welds is challenging, when we have a the thick, black 'slack' that is formed during the welding process, but on small surfaces it works without any problems.

ALUMINIUM

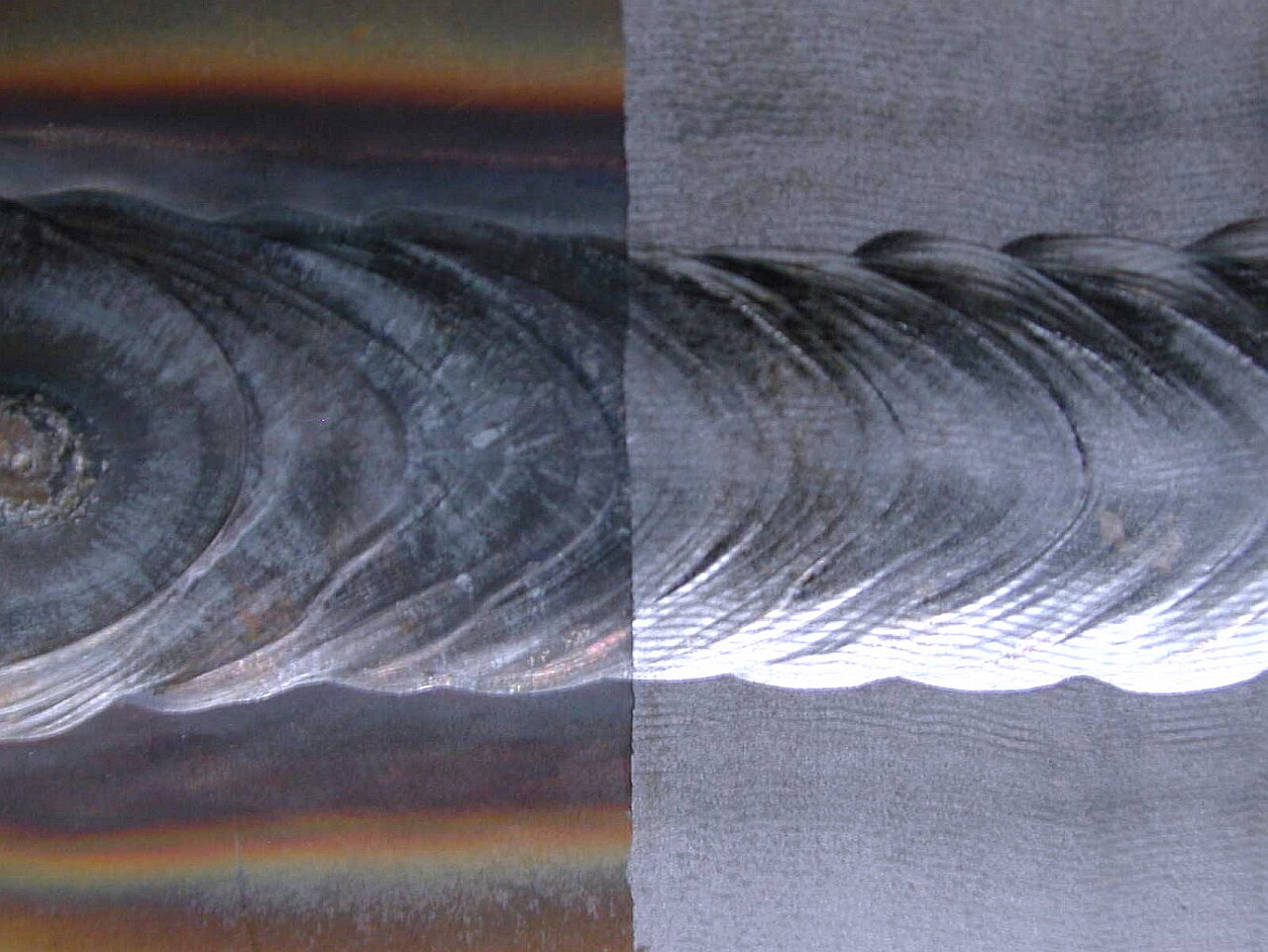

The effects of good weld preparation is determined by porosity. Comparing good and bad weld preparation, meaning all oxides were eliminated via surface cleaning on one part, and no cleaning was performed on another one results in: After good surface cleaning by laser you can see a lower porosity as a result of good surface cleaning. The less porosity in a weld, the less chance it will break over time. High speeds can be reached when preparing and cleaning the welds on aluminium, which makes laser cleaning a very effective solution.

STAINLESS STEEL

Stainless steel is as suitable for weld preparation and cleaning as aluminium. You can reach cleaning speeds varying from 1m to 1.5m per second. These speeds match up to common welding speeds, so it is easy to include a new laser cleaning system in an existing line. Needless to say is the fact that it is a very clean method, in comparison to traditional techniques as for example the use of chemical solvents.

PRE-TREATMENT BY LASER CLEANING FOR BRAZING AND WELDING

Cleaning LASER technology is ideal for cleaning steel and aluminum surface in welding preparation for industries that include automotive, precision tool manufacturing, shipbuilding and more. Laser weld preparation is a proven method with a long history of success in automotive brazing and welding applications.

Laser cleaning removes lubricants, ferrous and non-ferrous from metals to produces high quality welds and brazed seams that are smooth and pore-free offering highest stability and quality for visible seams.

Typical applications

-

- De-oiling

- De-greasing

- Removal of oxide layers

- Removal of hydrates

- Shop-primer removal

BENEFITS

-

- Precise treatment of joining surfaces over a wide range of material thicknesses

- No harm to galvanized layers of sheet steel when being pre-treated

- Typical rates for welding preparation for metals depend of the laserpower and the layer thickness:

- Aluminum sheet approx. 5 m/min

- Removal of shop primer up to 20 m/min

- De-oiling and cleaning of steel up to 10 m/min

WET CHEMICAL WASHING PROCESSES ARE NO LONGER NECESSARY

-

- No need for cleaning agents

- Minimum space required

- Direct line chaining or in-line chaining

- Significantly lower running costs

- Environmentally friendly process

- Optional process monitoring – 100% in-line cleaning monitoring possible

Zinc Laser Cleaning Application - Zinc coated steel laser Cleaning Applications

Laser cleaning is excellent for cleaning zinc-coated steel products prior to welding

The zinc laser cleaning process is done with high precision, removing any protective coatings, primers or organic coatings, and is suitable in preparing pre-painted or coated surfaces parts. Laser cleaning allows the metal surfaces of zinc layers to remain free of damage during the cleaning process. Moreover since the laser beam can be guided automatically with a very precise position and speed control, laser surface irradiation also enabled the fabrication of textured surfaces with improved wear, wettability and adhesion performance. This method is suitable for thin sheets as well as much larger components.

Laser cleaners are more effective than wet chemical washing processes when preparing zinc-coated steel for welding. When welding zinc-coated steel, three major problems can occur: high spatter amount, poor bead appearance, and high internal porosity. In addition, residuals left after welding can affect the corrosion resistance by interfering with the coating process.

Preparing the surface through laser cleaning produces higher quality welds and brazed seams that are smooth and pore-free. This provides higher stability and quality where there are visible seams. Layers can be removed uniformly and without residue.

Free of abrasion, the laser cleaning process is gentle on the material and the environment.

With their compact design, laser cleaning systems can be easily automated and integrated directly into the process chain. Laser cleaning systems are especially effective in welding preparation in the automotive and shipbuilding industries, as well as precision tool manufacturing, and more.

Weld Seam Laser Cleaning - Post-weld Heat Affected Zone Laser cleaning

In comparison of other cleaning methods, laser cleaning Machines provide significant advantages that quickly provide pay back of the initial investment:

-

Selective cleaning: lasers allow to work precisely where cleaning is needed – without masking

-

No post-processing - no demasking, no drying, no blast dust removal

-

Dry process: lasers work without any consumable cost for cleaning media and eliminate the need to recycle large amounts of cleaning by products from water or blasting dust